Data acquisition

Temperature registration

Temperature registration may be a key element of your business process. Take control of your process and the quality of your final product, whether you work in the pharmaceutical industry, food industry or hospitality.

Data acquisition

MX-GTW1 – HOBO MX Gateway

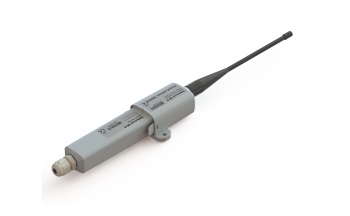

Flex-Sky-T-RH Wireless Temperature and Humidity Transmitter

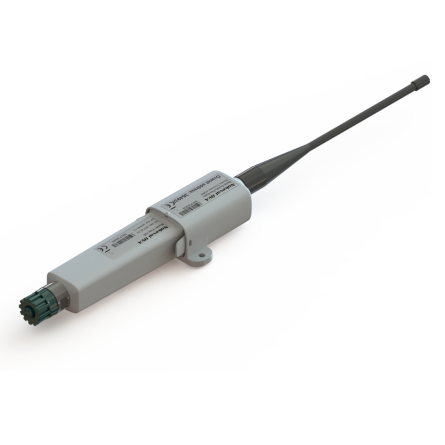

Flex-Sky-nSENS-HT-ENS Wireless Temperature and Humidity Transmitter

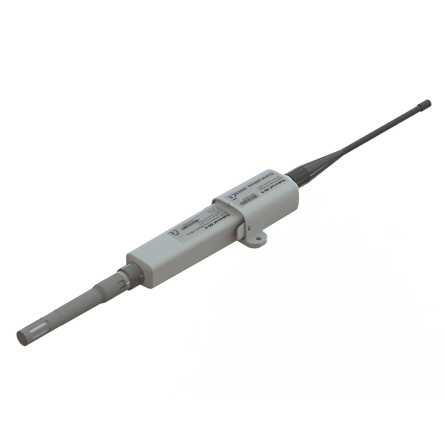

Flex-Sky-T Wireless LoRa Temperature Transmitter

Flex-Sky-CS – Nokeval

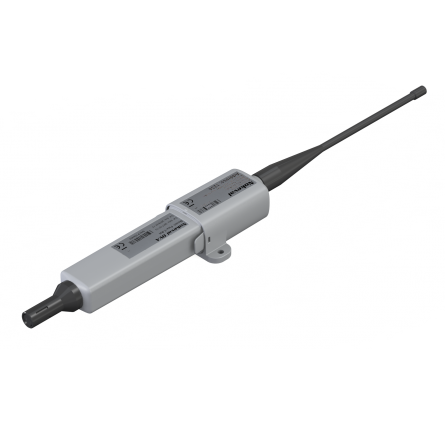

Flex-Sky-ES Wireless Temperature Transmitter

Data acquisition

T-EG4100 Energy Monitoring System

Kube-Sky-RHT Indoor Air Quality Sensor

T-EG-7000-2775 Rogowski Coil Current Transformer

Data acquisition

CX603 Ultra-Low Temperature Data Logger

Data acquisition