With the legalization of cannabis-based products for both medicinal and, in some locations, recreational use, the need has arisen to implement safety initiatives. Microbial contamination in either dried buds, extracted oils, or processed edibles can result in allergic reactions, respiratory complications, or foodborne illnesses. Additionally, degradation through chemical reactions can lead to changes in efficacy and potency. Water activity is an effective tool used in the food and pharmaceutical industries to ensure microbial, chemical, and physical stability. It provides the same level of safety and control in the cannabis market, and it is crucial for growers and processors to understand how to maximize water activity. Safety regulations for the cultivation and processing of cannabis-based products are currently addressed at the state level, resulting in inconsistent recommendations. As a result, not all states currently require testing for the water activity of cannabis. However, based on the established relationship with common safety and quality failures, water activity testing should be a key analytical test performed by everyone in the cannabis market.

MEASUREMENT OF WATER ACTIVITY OF CANNABIS

Measuring the water activity of dried cannabis flowers and other cannabis products can be challenging due to the high content of volatile compounds, including terpenes and cannabinoids. These volatile compounds can be absorbed by or interfere with the sensor used to measure water activity. If the sensor is not protected by any form of intervention, there is a risk of sensor degradation or inaccurate test results.

The electrolytic resistance sensor can accurately measure water activity in the presence of cannabis-related volatile compounds. However, to prevent it from deteriorating over time, the sensor must be protected with a filter. Novasina recommends the eVC-21/eVALC combo for the Lab-Touch and LabSwift and the eVC-18/eVALC combo filter for the Labmaster NEO when measuring cannabis.

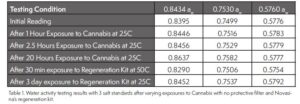

Recently, Novasina conducted a test study using a LabMaster NEO, exposing the electrolytic sensor to cannabis flowers without any protective filters for various time periods to gain more insight into the influence of cannabis-related volatile compounds. The results of this study are presented in Table 1.

The study showed that exposure to cannabis without a protective filter resulted in changes in water activity measurements according to the Sal-T standards. However, the degree of change was not the same for all standards. The change due to exposure increased with the water activity of the standard, with the 0.576 aw standard showing a maximum change of 0.003 aw, the 0.753 aw standard showing a maximum change of 0.005 aw, and the 0.8434 aw standard showing a maximum change of 0.02 aw. This suggests that higher water activity measurements are more affected by sensor exposure to cannabis than measurements below 0.753.

If all these results were collected without a filter, they represent a worst-case scenario, and the effects would be reduced and delayed when the appropriate protective filter is used. The results in Table 1 also indicate that the volatile effect on the electrolytic sensor due to cannabis can be reversed through prolonged exposure to the regeneration kit.

The results of this study, combined with customer feedback from those conducting frequent tests on cannabis, have led to updated best practices for hemp testing. Novasina’s current recommendations for testing cannabis are as follows:

- Use the recommended filter for the instrument used for testing (eVC-21/eVALC combo for the LabTouch and LabSwift, and the eVC-18/eVALC combo filter for the Labmaster NEO).

- Replace the filter approximately every 1-2 months.

- Purchase a regeneration kit from Novasina and use it regularly. A. Some users currently use the kit every evening, between tests, and experience no issues, even with extreme test frequencies. B. If the test frequency is less than 5 times per day, the use of the regeneration kit can be limited to only when the verification of salt standards falls outside the tolerance limits.

- Do not leave cannabis samples in the instrument for an extended period when not testing.

WATERACTIVITY AND CHEMICAL STABILITY

In cannabis biomass and food with a water activity of less than 0.70 aw, microbial spoilage is no longer the most likely cause of spoilage. However, products in this range do not have unlimited shelf life.

So, what other causes of spoilage are likely to terminate shelf life? For cannabis biomass and food with a water activity in the range of 0.40-0.70 aw, chemical degradation is a strong candidate as reaction rates are at their maximum. Chemical reactions such as Maillard browning, lipid oxidation, enzymatic reactions, and others can affect the taste, appearance, and nutritional value of biomass or food. Water activity influences reaction rates by lowering activation energy, increasing mobility, and raising the rate constant. Therefore, reaction rates are better correlated with water activity than with moisture content. Generally, reaction rates increase as water activity increases, but specific correlations depend on the type of product and the type of reaction (Figure 1). Most reactions peak in the range of 0.70-0.80 aw due to dilution at high water activities, but lipid oxidation is the only reaction that increases at low water activity.

For marijuana, the reaction that is likely to most significantly impact quality is the loss of THCA due to decarboxylation, which will reduce potency. For cannabis products in the form of edibles, the reaction most likely to compromise quality is Maillard browning for products with proteins and reducing sugars or lipid oxidation (rancidity) for samples with high fat content. These reactions are complex and pose issues through the production of odor and taste compounds. When the reaction has progressed and produced enough undesirable compounds or when there is a loss of THCA, the product becomes unacceptable to the consumer. The impact of chemical reactions can be minimized by limiting reactants such as reducing sugars for Maillard browning, oxygen for rancidity, and through decarboxylation. Lipid oxidation is unique because the rate not only increases as water activity rises but also at low water activity, challenging the general rule “lower water activity is better” in all cases.

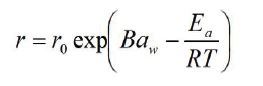

To help determine the ideal water activity to slow down the breakdown of chemicals, the reaction rate can be predicted using shelf-life models. For these models to be effective, they must account for the effect of both water activity and temperature. The only fundamental shelf-life model that incorporates both water activity and temperature is the hygrothermal time [2]. This model is derived from a form of the Eyring equation for rate change and the Gibbs equation for free energy and is given by:

where T is the temperature (K), R is the gas constant (J mol-1 K-1), Ea is the activation energy (J mol-1), B is the molecular volume ratio, aw is the water activity, and r0 is the rate at standard conditions. In practice, the values for B, Ea/R, and r0 will be unique to each situation and are empirically derived through iterative methods such as the least squares method. Once these constants are known, the hygrothermal time model can be used to determine the rate of change at different temperatures and water activities, thereby estimating the shelf life for a specific product under those conditions. This model can help determine the ideal water activity at which chemical breakdown is minimal for cannabis biomass or edibles, maximizing their shelf life. Identifying and processing products to this ideal water activity, thus preventing microbial growth and minimizing chemical breakdown, is essential for maximizing the shelf life of cannabis products.

WATER ACTIVITY AND STORAGE STABILITY

Harvested cannabis (marijuana and hemp) must be adequately dried to enable storage and transport. As explained earlier, water activity determines whether molds, yeasts, or bacteria can grow on the biomass during storage. Generally, dry biomass will have a water activity in the range of 0.60 to 0.70 aw.

While pathogenic bacteria pose the greatest risk at the typical water activity of biomass, molds are likely to be a more common source of contamination. Almost all molds, except for a few rare xerophilic species, stop growing at water activities lower than 0.70. Although molds themselves are not particularly dangerous when consumed, they can produce mycotoxins as part of their metabolism, which can cause severe reactions in some individuals. Additionally, the presence of actively growing mold also indicates the presence of mold spores. This can be particularly hazardous for products that are inhaled, as mold spores in the airways can trigger asthma symptoms.

Therefore, the water activity of all harvested biomass being stored or transported should be lower than 0.70 aw. This means that testing water activity is essential for both growers and processors. The water activity of edible cannabis products can also change during storage and transport. For example, baked edibles typically have a higher water activity and should be tested to ensure they are processed to water activities lower than 0.86 aw to prevent the growth of pathogenic bacteria. Subsequently, their water activity should be maintained within the ideal water activity range during storage to prevent both an increase in water activity to unsafe levels and a decrease in water activity that can cause unwanted changes in texture. To achieve this, edibles should be packaged in suitable moisture barrier packaging. The exact packaging requirements to prevent changes in water activity can be modeled and predicted, but the derivation and application of these models fall outside the scope of this document.

THE KEY SPECIFICATION

Water activity plays a key role in ensuring the safety of cannabis products and maximizing shelf life. For many in the cannabis industry, water activity may be a new concept, and those familiar with it may only associate it with its role in regulating microbial growth. In reality, however, microbial spoilage is not always the most likely cause of shelf-life issues with cannabis products. Water activity is related to all the common ways products can spoil and can, therefore, be the most crucial test that can be performed on everything from harvested biomass to edibles.

Questions or want more information about AW meters? Feel free to contact us!